Advancing, Together with PALACOS® R+G

For more than 50 years PALACOS® R+G has been synonymous with excellent product quality to provide patients with better outcomes.

PALACOS® R+G relies on a wide range of people working together to achieve success, including:

- forerunners in material development

- first users and pioneers in arthroplasty

- those who produce and optimise PALACOS® R+G day in, day out

- healthcare professionals who use PALACOS® R+G for the benefit of their patients.

PALACOS® R+G is our success story that we can all be proud of.

Thank you for decades of trusted collaboration for best patient outcomes.

Who are the People Behind PALACOS® R+G?

For the 50th anniversary in 2022, they share their stories about their experiences with the product.

Prof. Dr. Klaus-Dieter Kühn, Medical University of Graz

"PALACOS® R+G has been synonymous with excellent product quality with optimally combined, high-quality raw materials and active ingredients."

PMMA bone cements are a passion for Prof. Dr. Klaus-Dieter Kühn. Because of its "groundbreaking importance in pharmaceutical technology," he has been researching this field for decades. It is his personal concern to share his extensive knowledge with young surgeons at the Medical University of Graz. Prof. Kühn attributes his fascination with PALACOS® to its optimal manufacturing process and high quality.

Dr. Pablo Sanz Ruiz, Orthopaedic Surgeon

“The more we got to learn about bone cements, the better we understood that there are big differences. We have chosen PALACOS® R+G since it has the best antibiotic elution.”

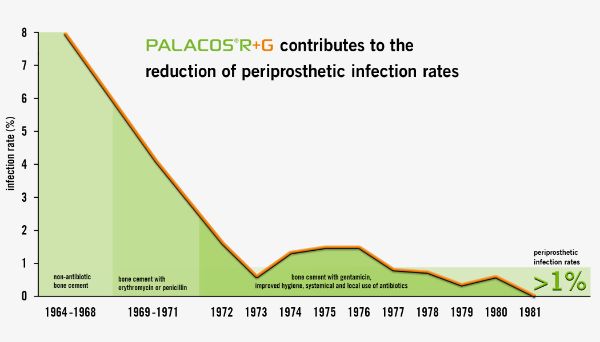

Orthopaedic surgeon Dr. Pablo Sanz Ruiz works at the General University Hospital Gregorio Marañon and conducts research at the Complutense University of Madrid, Spain. The reduction of periprosthetic infections is one of his greatest concerns. With PALACOS® R+G he was able to significantly reduce infections rates at his hospital and increase cost-efficiency.

Dr. Matthew Dietz, Orthopaedic Surgeon and Associate Professor

“What makes PALACOS® R+G so special is the consistency and reliability. In the operating room, it seems like every day there’s something different. To have something be there that you can trust and rely on in each case, I think is really important for the excellent outcomes for the patient.”

Dr. Dietz works as an Orthopaedic Surgeon and Associate Professor at West Virginia University specializing in hip and knee replacements and complicated revisions with research interest in implant associated infections.

Ralph Bretschneider, Production Manager at Heraeus Medical

"I have been part of the PALACOS® R+G production team since 1987. Even back then, I was impressed by the fact that this bone cement is hard and yet elastic. It is very important that it always cures in the same way. That is a quality criterion. That's why we are very meticulous in the production of PALACOS® R+G. Quality definitely comes before quantity. That is important to us. We want our customers to get a product of which they can be sure that they are holding something good in their hands. In the end, of course, patients should also benefit from it. I myself had a hip replacement and I know how I felt when I was in pain and I couldn't walk. It is something special to produce a product that helps people to be able to walk again and not be in pain."

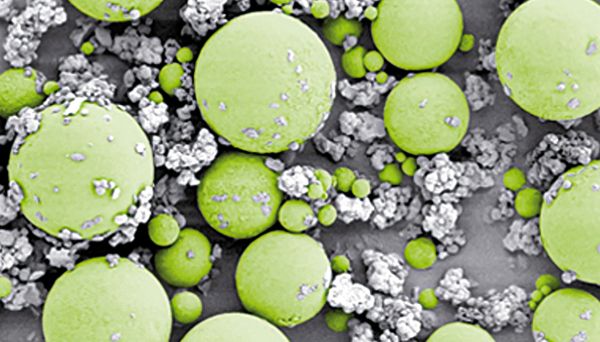

Bettina Hinkelmann, Laboratory Employee at Heraeus Medical

"I work with PALACOS® R+G in the laboratory, where we test whether changes in the production process affect the quality of the bone cement. Processing times, compressive and bending strength, temperature maximum, intrusion depth into the bone – all this is tested in our laboratory. Personally, I find the test for bending and compressive strength very interesting. These are mechanical tests that focus on the strength and elasticity of the bone cement. It must not be too brittle, so that it breaks quickly. But it must also not be too soft to ensure a certain stability. We carry out these and other tests regularly. In this way, we help to ensure that PALACOS® R+G has a high and consistent quality and can provide patients, who unfortunately need joint replacement, with pain relief and bring them back their quality of life."

Dr. Carel H. Geerdink, Orthopaedic Surgeon

"The choice of bone cement is connected to the implant survival."

Dr. Geerdink works as an orthopaedic surgeon at Ikazia Hospital in Rotterdam, the Netherlands, and specialises in sports orthopaedics and traumatology. The Ikazia Hospital puts special emphasis on the well-being of its patients.

Andreas Seitz, Operating Theatre Manager

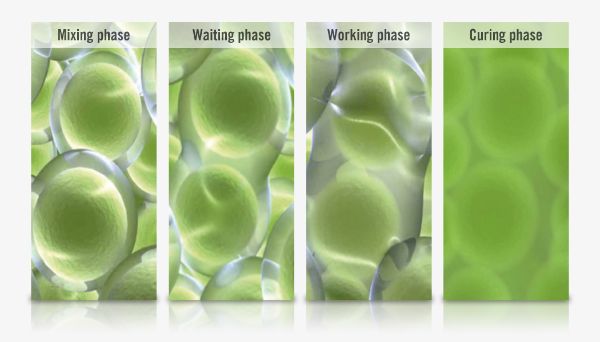

"I appreciate the consistency of this cement, which always tells me which phase it is in. With this cement you already know by feel what kind of strength it will develop, when it will be ready, when you have to stop."

Andreas Seitz is the operating theatre manager at medius Kliniken, Germany, and responsible for the operating theatre staff at three locations. He oversees a team of 200 operating theatre nurses who provide inpatient care to 46,000 patients and outpatient care to over 125,000 patients each year. The medius Kliniken have an excellent reputation in the Stuttgart area in the field of artificial hip care.

A Journey Through Time with PALACOS® R+G

1901 – It all Starts with ‘Organic Glass’

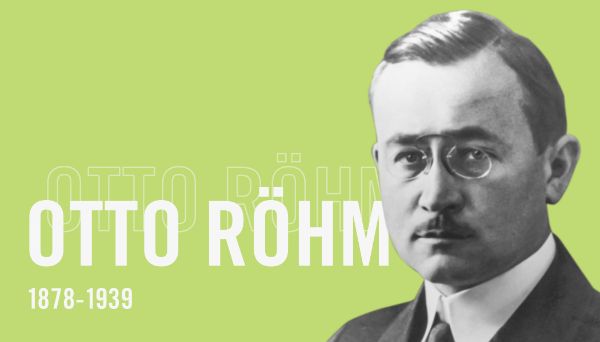

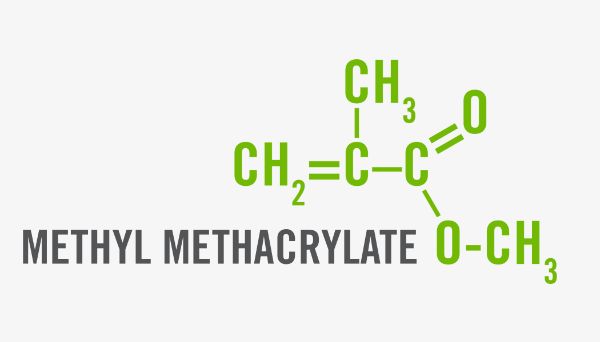

The chemist Otto Röhm lays the foundation for the manufacture of the new plastic polymethyl methacrylate, or PMMA, with his dissertation entitled ‘Polymerisation products from acrylic acid’ (original: „Über Polymerisationsprodukte der Acrylsäure“). Röhm calls it ‘organic glass’ – today, it is better known as plexiglass.

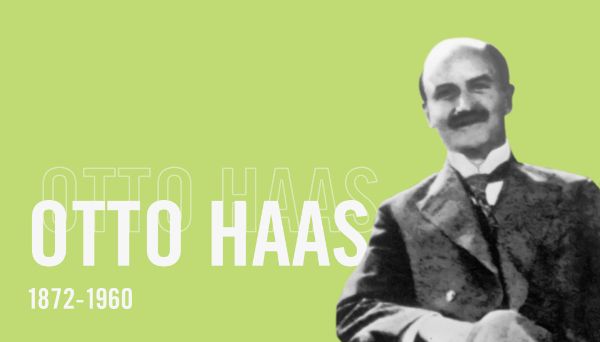

1928 – Industrial-scale Manufacture by Röhm & Haas

Otto Röhm and Otto Haas make refinements to the acrylate at their research lab and develop a method for synthesising methyl methacrylate (MMA) on an industrial scale.

1935 – First Artificial Dental Prosthesis with MMA

Walter Bauer, head of the Röhm & Haas research lab, patents the process for manufacturing dental prostheses using methyl methacrylate (MMA). At the same time, the lab continues to work on further application areas.

1936 – Heraeus (Kulzer) Patents Heat Curing Moulding Compound

Heraeus (Kulzer) discovers that mixing ground PMMA cement powder and monomer liquid creates a pasty compound, which sets when heated to 100°C with benzoyl peroxide (BPO). This process is known as ‘heat curing’.

1941 – PMMA Used in Plastic Surgery for the First Time

Kleinschmitt uses pre-formed and pre-cured PMMA plates of the heat-curing polymer PALADON® 65 for the first time to repair cranial defects.